Black metal ore mining and selection products

More details >>

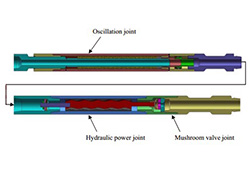

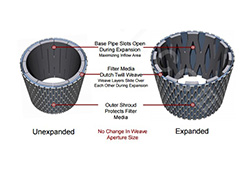

This solution introduces the well - cleaning operations for optimizing wellbore storage and circulation environment. With the increase of deep well and ultra deep well developing, drilling is becoming more and more difficult, and oil companies are more and more sensitive to the input-output ratio. Problems during drilling and oil recovery. Expandable well technology solves the above problems and becomes one of the core technologies of the oil drilling industry in the 21st century. This solution Introduces the Expandable Tubular Technology, involving Expandable casing and Expandable screem.

More details >>

Best solutions and tools for improving drilling efficiency and rate of penetration (ROP). There is a developed coring technology and matching coring bits for conventional coring form keeping coring directional and horizontal wells coring coring in air drilling hydrates pressure and temperature preservation coring cores post treatment etc. At the moment there are two series and 11 types of coring tools to meet the needs of conventional coring form keeping coring and sealed coring for the soft broken deep wells and shale formations with various wellbore sizes and the core recovery percentage is more than 90%.

More details >>

Multi-heat Fluid Generator ERUI’s Enhanced Oil Recovery (EOR) methods and case studies of successful projects. Using the rocket launch principle, fuel (diesel oil, crude oil or natural gas) and air are injected into the generator to burn, steam, nitrogen and carbon dioxide are composed of high temperature and high pressure multi thermal fluid, which can be widely used in the development of heavy oil field.

More details >>

Due to high steam injection pressure and low permeability. Thin layer low-seepage heavy oil reservoirs accompanied by low production and low efficiency, have great difficulties in reserve utilization Fracturing sand prevention process is a kind of production increase and sand prevention technology, which has strong theoretical pertinence and Strong field adaption.

More details >>

All about Expandable Tubular Technology: 1. Problems the industry faced; 2. Introduction of Expandable Tubular Technology; 3. The Advantages of Expandable Tubular Technology; 4. Applications of Expandable Casing Technology

More details >>

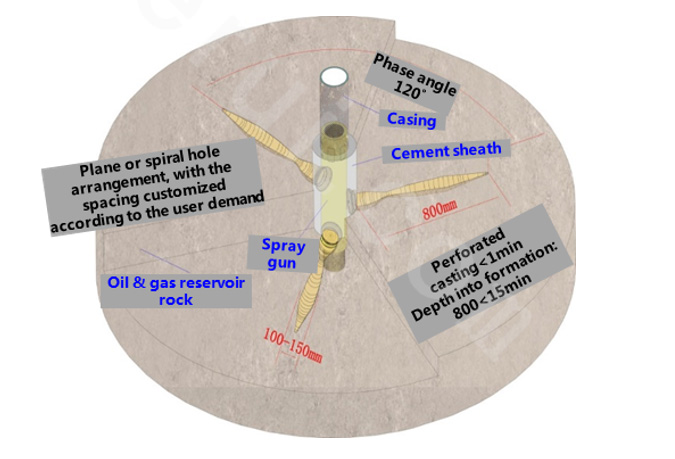

In the development of the oil and gas reservoir, deep formation plugging always happens Unfortunately,the conventional plug removal technologies usually have some shortages, such as complex procedure, high operating cost, short effective period, and so on As for this, this article introduce an mature efficient plug removal technology, named hydraulic sand jet perforation, and the technology has lots of advantages, including simple procedure, low operating cost (completion in several hours), long treatment radius and good effect (treatment radius above 1m)

More details >>

With more and more focus paid on the metal corrosion and protection measures, the cathode protection technology is given with guidance standards on the national level especially for the buried steel pipeline and port engineering facilities, also, some mandatory requirements are made for cathode protection of ships and other equipment during construction According to this, develop a Cathode Protection Intelligent Detection System.

More details >>

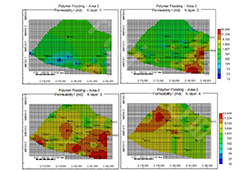

The conceptual scheme is mainly aimed at T oilfield polymer flooding test area at South America. In early stage, most wells had response, and the overall fluid and oil production in pilot area increased. In mid-to-late stage2C multiple wells had a sharp rise in polymer concentration and glide in oil production.The results of pilot test differ from prediction. The water cut almost reached 90 until 2014 After a comprehensive analysis of information, find out the question crux. According to different conditions, puts forward some countermeasures to improve the effect of polymer injection and the follow-up research work.

More details >>

This solution mainly introduces common troubles of standard conventional wellhead, Maintenance and parts solutions, Remove and repair tools and Field testing tools.The most commonly used valves in wellhead equipment include plate gate valves, choke valves, safety valves and ball valves. Due to the abrasion, vibration and corrosion caused by the media, the aging deformation and improper operation of the sealing parts, the valve can leak easily.

More details >>

Three-phase separator plays a more and more important role in crude oil dehydration Its dehydration effect directly influences the crude oil temperature rise costs of the Combination Station and the stable and normal operation of crude oil as well as the crude oil transportation indexes The Efficient Three-phase Separator changes “crude oil dehydration” into “oil removal in the water” Its function can replace free water removal unit and electric water removal unit,Its safety is much higher than that of electric water removal unit Besides, it also enjoys considerable economic benefits

More details >>

Sand control in powder sandstone, argillaceous fine sand rock oil well and gas well development has always been a difficult problem In the case of fine sand, the sand filter pipe will be seriously blocked, and the production capacity will decrease rapidly after being put into operation The problem of gas well is more prominent, due to the blockage of the sand filter pipe, the production capacity is reduced rapidly on the one hand; on the other hand, the other blockage of the other side causes partial concentration of the gas pressure, and the sand-filtering pipe blow-through will cause the sand-proof failure, which is a serious problem that is common and difficult to solve The problems mentioned above can be solved effectively by shaft block-free chemical sand-fixing technology.

More details >>